Case Studies 1. Oil Free Case Study

Date of compressed air installation: April 2016

Location: A blue-chip company in Shropshire

Description: Our customer required a new oil free air compressor to connect to an existing dryer. The dryer was still serviceable and the customer, renowned for their environmental concerns and commitment to lowering their carbon footprint, wanted an energy-efficient, reliable and cost-effective air compressor which would work with their existing dryer.

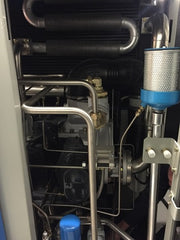

Solution: The SCR100GV, a 75kw variable speed drive (manufactured by Innovance, who specialise in high torque application cvsds) screw compressor with an IE3 motor (for optimal efficiency), double skin doors, stainless steel pipework and German GHH Rand air ends. This compressor fitted almost seamlessly to the existing drum dryer, and, by the inclusion of a vsd, could match air demand, thus eliminating wasteful off-load energy. Further energy savings were made by controlling the drum dryer & dryer fan itself with ABB ACS355 & ACS580 series variable speed drives.

Benefits: Significantly impressed with the build quality of the SCR oil free compressor, the end customer has seen:

- A reduction in servicing costs

- A significant reduction in energy usage (and thus costs)

- A more stable and cost-efficient operation (the unit was purchased with a 5 year warranty).

- A new compressed air system which still made use of - and seamlessly integrated with - their current equipment, thus making the very best of the anticipated pay- back time of their newly purchased compressor