AIR COMPRESSOR ENERGY SURVEYS

Are you hemorrhaging money on your compressed air costs? It might surprise you to find out that even a small air compressor can cost you thousands of pounds a year to operate.

How do I know how much my compressed air is costing me? Start with our compressed air energy savings calculator

Compressed air is one of the most important utilities for industries, accounting for 10% of the electrical consumption in the UK. Essentially, it's the fourth utility.

The need to generate compressed air in the most energy-efficient manner is an issue of vital importance.

Savings made in your compressed air systems will have a significant impact on both your company's running costs and the environment. Do you know how much your compressed air is costing? The cost of electricity for medium-sized companies has tripled over the last 13 years, making producing compressed air a costly business. So imagine producing the same amount of air...but it costing you less.

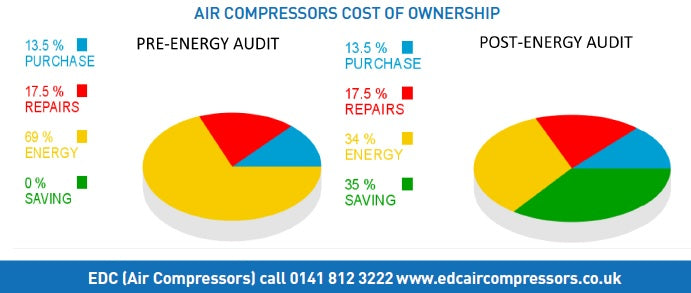

EDC Air Compressors can undertake an energy survey on your compressed air system, providing a detailed report with the potential to save you up to 30 - 35% on your compressed air running costs. See further information on the new industry standard for industrial air compressor energy surveys: ISO11011 for air compressor systems. Or see how we can comprehensively deal with air compressor leak detection.

We will undertake an audit of your existing system - giving you a comprehensive profile of your current compressed air usage - and provide a clear & comprehensive report on how to reduce your running costs: Where your leaks are, how your maintenance can be improved, how suitable your existing system is for your actual requirements.

In analysing, optimizing and monitoring your compressed air system, you will be able to both reduce your costs and increase your efficiency; lowering your carbon footprint and freeing capital for reinvestment and growth.

Further savings can also be made by taking out one of our compressed air preventative maintenance service agreements. These can future-proof the purchase of your compressed air system, fixing service costs and ensuring that your equipment is performing to its maximum potential whist receiving the correct servicing at the correct intervals from our industry qualified professionals.

Contact us today for a no obligation energy survey: Tel: 0141 812 3222 or email us at: compressors@edcscotland.co.uk

Estimated energy saving of up to 30 to 35% can often be achieved after an air compressor energy audit is undertaken

High Quality, Low Cost – Can an Air Compressor Energy Survey stop you leaking money? Or is it all hot air?

Air compressors are the backbone of many industrial processes. We can’t run our businesses without them – but they are inefficient systems ….on their own. Change this: contact us for an energy survey today. Here’s why you should optimise the potential of your air compressor system – integrating it into your company’s overall energy reduction strategy: reducing your carbon footprint AND saving money in energy costs.

Energy Audits: If you can’t measure it, you can’t manage it. An energy audit from EDC Air Compressors can measure and advise on all the issues listed below. All of which can save you significant amounts of money on your air compressor system.

85% of your air compressor’s energy is lost in heat: What could you do with the energy you’re wasting? Heat recovery? Can you utilise this energy in other processes in your plant and avoid paying for energy twice?

Stop the leaks: If your system has leaks (you can hear them after hours, or find them via ultrasonic equipment) you could be losing thousands per year: 4-5mm can equal a loss of over £1k per annum…..so it’s worth the test. If you’ve already identified the leaks (and have been depending upon self-repair) it’s probably time to call in professionals. It’s likely your system is in need of an upgrade or overhaul and may have more leaks than you’ve been able to identify.

Take the pressure off: Are you generating air at maximum pressure… all the time? Why? Can you reduce your output without reducing your operational efficiency? We can tell you if this is possible – and small reductions can save thousands.

Switch off!: When appropriate to the system, air compressors can be switched off when not in use. Leaving them running might be convenient – to your energy supplier – but not to your business. 35-40% of full load is used by an air compressor on offload. If you don’t need it: switch it off.

Should you be looking at a variable speed drive compressor, or retrofitting one? What energy savings can you make from this? No inrush current, no pressure fluctuations, energy creation meets energy demand (so optimum efficiency) BUT harmonics, system spec and cooling requirements all need to be taken into consideration before considering a variable speed drive retrofit.

Service your equipment: Leaks need to be repaired, but they can be routinely diagnosed during a system service – and once they are repaired, your system can be re-assessed to advise you of the savings. Of course, routine system maintenance would probably have prevented the leak in the first place…an additional 2.5 psi of operating pressure can add an additional 1.5% to your operating costs per annum. Money you’re literally throwing into the air…

A free air compressor energy survey from EDC Air Compressors could:

· Save your company significant energy & maintenance costs

· Advise if your system is sized and operating efficiently - are your air compressors suited to their applications?

· Improve & stabilise the reliability of your overall system

· Prevent unexpected down-time

· Enhance productivity

· Reduce your carbon footprint

· Maximise the pay-back time of your air compressor

· Reduce your CAPEX and OPEX costs

Your compressed air energy audit should be holistic in its approach: your compressed air system is interconnected & linked to your entire operating system. EDC can identify any problems and supply the solutions, assisting you in achieving operational excellence. Call 0141 812 3222 today.