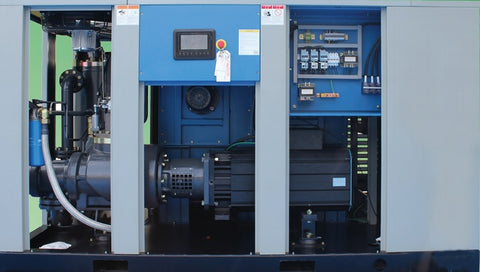

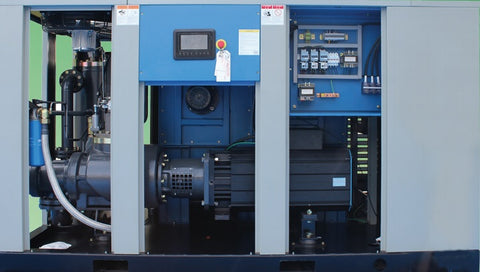

EPM & EPM2 ULTRA HIGH EFFICIENCY SCREWS

From 15 - 110 kW, with up to 25% more flow compared to standard screw compressors. Features include:

- A VSD cooling fan - varying the cooling fan speed reduces noise and energy consumption

- A touch screen controller - to ensure intuitive ease of operation

- Pressure scheduling - to reduce energy usage at weekends and night

- Low speed airend - A low rotation speed reduces wear and load on components

- Unique dual layer oil cooled PM motor - the EPM series uses the compressors oil cooling circuit to keep the motor cool even during prolonged periods of low speed operation, whilst the IP65 rated motor makes it ideal for dusty environments. An added benefit? PM motors don't use traditional bearings - so the motor is maintenance free!

View the EPM air compressor brochure.

Use our air compressor energy calculator to find out how much your compressor is really costing you.

The new EPM2 range of compressors. The most energy efficient screw compressors on the market? See for yourself.

With every component part designed for energy-efficiency and longevity, the EPM2 range (from 55kW to 160kW) can save the average end-user 35% in energy costs.

It's the result of 20 years of careful planning and design execution. Two decades well spent as it has been granted three patents and an energy star award. It's also independently tested by SGS to ISO1217 - the industry standard which confirms it produces the air flow it claims to.

It utilises large, oversized airend rotors, whilst the slow running airend also uses multipoint atomised injection technology during compression, ensuring that the airend performance is maintained. This guarantees optimum an performance curve, resulting in high air output. The IE4 permanent magnet motor is maintenance free and the bearing free, liquid cooled, PM motor also requires zero maintenance - and has an expected lifespan of over 100,000 hours. Yes, 100,000 hours. But seeing is believing...